Description

|

DIMENSIONS |

ITEMS |

||||||

|

D |

LU |

DS |

LS |

LT |

Ang. Ass |

Z TOT |

SKU |

|

10 |

18 |

12 |

50 |

78 |

0° |

1 |

FPS3009001 |

MICROTECH

HIGH PERFORMANCE TOOLS

T +39073357879 / +390733579649

Email: microtechdia@microtechdia.com

MICROTECH

Via Leonardo Da Vinci 21

Appignano (MC) 62010

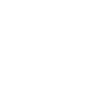

Pcd shank cutter Z1 for lamello.

|

DIMENSIONS |

ITEMS |

||||||

|

D |

LU |

DS |

LS |

LT |

Ang. Ass |

Z TOT |

SKU |

|

10 |

18 |

12 |

50 |

78 |

0° |

1 |

FPS3009001 |

| NUMBERS OF WINGS | 1 |

|---|---|

| ENGAGED TIPS | 1 |

| ALTEZZA PCD | 3 mm |

| TYPE OF CUTTING | DIA |

| TYPE OF PLUNG TIP | PCD no drill |

| AXIAL ANGLE | 0° |

| TOOL BODY | Steel |

| MAXIMUM NUMBER OF LAPS | 24.000 R.P.M. |

| SHARPENING TYPE | Lamello |

| FEEDING SYSTEM | Mechanic |

| MATERIALS | Hard wood, Light wood, MDF HDF, MDF HDF Double face laminate, Particle board, Particle board double face laminate, Plywood, Plywood double face laminate |

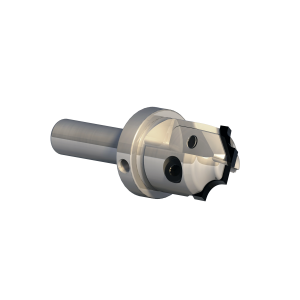

Insert PCD shank cutter multitasking with interchangeable profiled knife and center cutting knife. Suitable for profiling on different materials such as solid wood, laminated chipboard panels, playwood MDF, HDF, HPL, Trespa, Corian, Carbon fiber panels (CFRP), Teflon, plaxiglass, aluminnium and others plastic materials.

To be used also on finishing passage on nesting operation after sizing. So many are the advantages of this tool: Constructive geometries that eliminate any mismatch between the cutter body and the PCD insert ensuring high positioning of inserts and repeatability. Another advantage is that the PCD insert is worked in a cold conditions without undergoing any kind of stress due to welding operation. So the PCD inserts keep all the features, increasing the tool life and cutting quality.

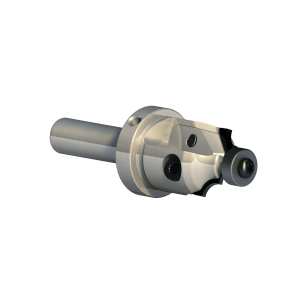

Insert PCD shank cutter multitasking with interchangeable profiled knife and copy bearing. Suitable for profiling on different materials such as solid wood, laminated chipboard panels, playwood MDF, HDF, HPL, Trespa, Corian, Carbon fiber panels (CFRP), Teflon, plaxiglass, aluminnium and others plastic materials.

So many are the advantages of this tool: Constructive geometries that eliminate any mismatch between the cutter body and the PCD insert ensuring high positioning of inserts and repeatability. Another advantage is that the PCD insert is worked in a cold conditions without undergoing any kind of stress due to welding operation. So the PCD inserts keep all the features, increasing the tool life and cutting quality.

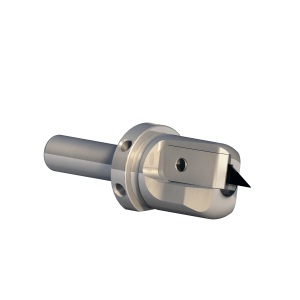

Insert PCD shank cutter with interchangeable profiled knife Z=1. Suitable for profiling or engravings operation on different materials such as solid wood, laminated chipboard panels, playwood MDF, HDF, HPL, Trespa, Corian, Carbon fiber panels (CFRP), Teflon, plaxiglass, aluminnium and others plastic materials.

So many are the advantages of this tool: Constructive geometries that eliminate any mismatch between the cutter body and the PCD insert ensuring high positioning of inserts and repeatability. Another advantage is that the PCD insert is worked in a cold conditions without undergoing any kind of stress due to welding operation. So the PCD inserts keep all the features, increasing the tool life and cutting quality.